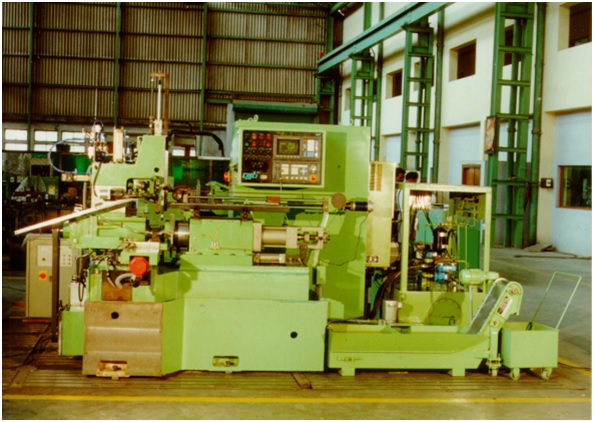

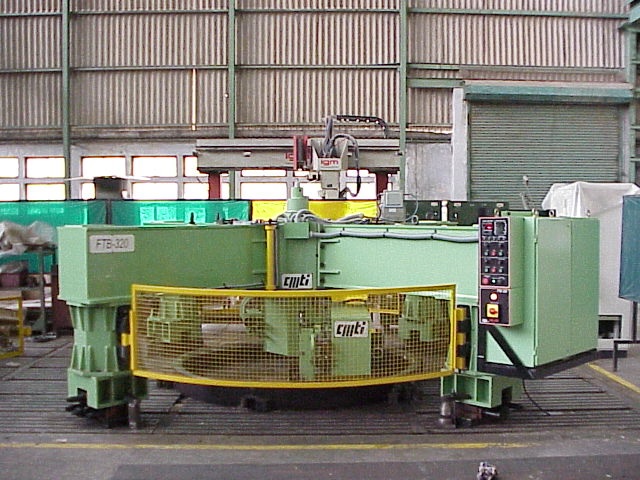

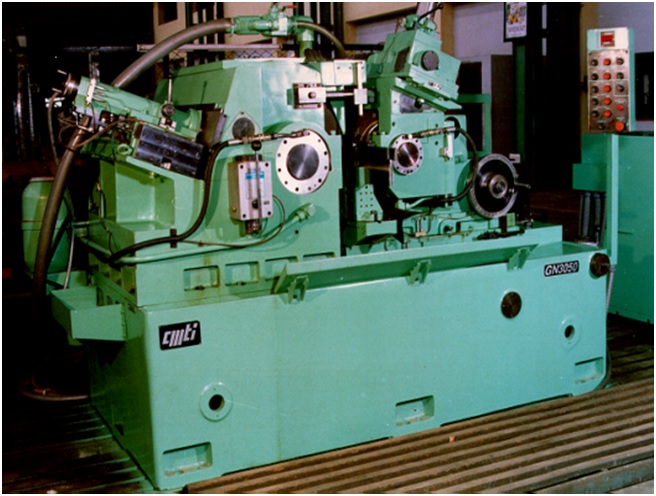

Welcome To CMTI

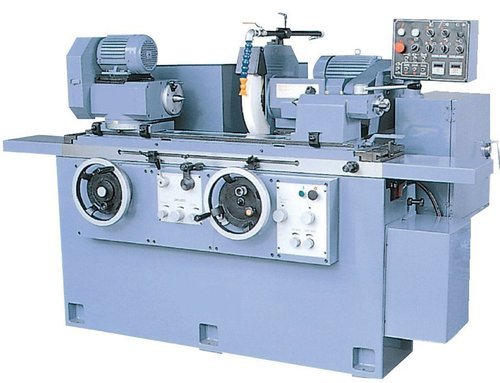

The Central Manufacturing Technology Institute (CMTI) being a National Research and Development organization stands as a pioneering force, dedicated to shaping the manufacturing landscape through its unwavering focus on science, technology, and innovation. By driving the development of new technologies, catering to customer needs, providing valuable services, and fostering an environment of advanced technology intervention, CMTI solidifies its position as a catalyst for growth, progress, and excellence in the manufacturing industry.